Industrial molding with TPU

The products in thermoplastic polyurethane (TPU) are characterized by a high combination of elasticity and durability ensured at each temperature. The TPU that we usually use is a type of polyester-based compact polyurethane suitable for molding on injection molding machines.

Thanks to its superior mechanical properties, elasticity and resistance to tear and tensile strength, is particularly suitable to be used in high stress areas.

Thermoplastic polyurethane under certain conditions is considered to be the most abrasion-resistant elastomer.

The hardness we normally print is between 80 and 95 ShA.

We have a fleet of 60 to 300 tonnes for injection molding.

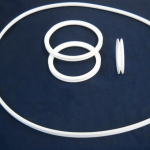

Some products made with TPU molding

Fundamental Characteristics

- high wear and abrasion resistance

- high traction and tear resistance

- excellent cushioning capacity

- high flexibility at low temperatures

- high resistance to oils, fats, oxygen and ozone

Main Productions

- shock absorber bumpers

- gaskets and seals

- bushings

- O-ring, V-ring

- sleeves

- washers

- anti-vibration plates

- molded metal-TPU or plastic -TPU

- technical articles in general

Our main customers